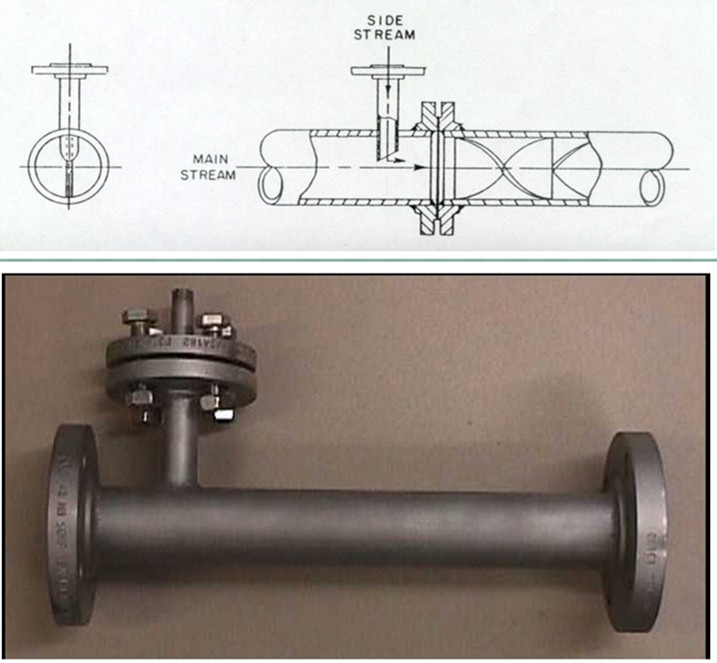

The Chemplant Static Mixer is an inline mixing device with no moving parts. This makes it a unique piece of processing equipment as it requires no external power source and is completely maintenance free. The Chemplant Static Mixer produces a homogeneous blend or dispersion in a laminar, transitional or turbulent flow regime within a very short length of pipe.

OPERATION

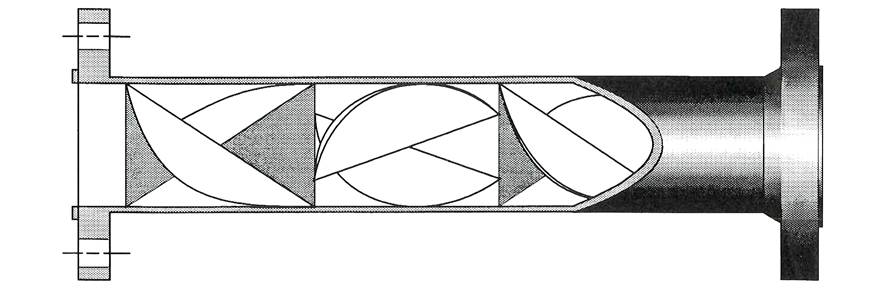

Chemplant Static Mixers have elements which rotate the fluid around a hydraulic centre. This directs flow radially to the walls and back to the element regardless of the velocity or Reynolds number. The elements are combined with alternating offsets to maximize mixing efficiency by utilizing the action of momentum reversal and flow division.

Turbulent Flow:

Mixing occurs mainly as a result of momentum reversal. This means that the fluid is forced to change the direction of rotation by the twist of the following element.

Laminar Flow:

Mixing occurs as a result of flow splitting and rotation. This causes build up of increasing numbers of layers of material and these layers split each time the fluid passes between two elements thus causing mixing.